The Problem

If waxy oils in produced fluid cool below their Wax Appearance Temperature (WAT), wax deposits will form in the tubulars. If untreated these can cause;

■ Restricted flow.

■ Reduce pump efficiency.

■ Artificial lift damage/downtime.

■ Complete loss of production.

■ Loss of revenue.

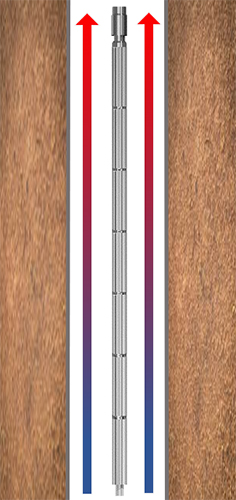

THOR as a Solution

A THOR system attached to the production tubing and placed below the artificial lift pump would keep the produced fluid warm and above WAT, giving the following benefits;

■ Targeted heating of fluid to + 5-10oC [ 9-18 oF] above WAT.

■ Lower fluid viscosity / Increase pump efficiency.

■ Remove / delay requirement for pump retrieval/remediation.

■ Increase production.

■ All in a small, high efficiency package with a low energy requirement.